Wind turbine propeller modeling in heliciel

Tidal turbine modeling in heliciel Kaplan propeller modeling in helicielUnderstand how the wind turbine pump works :

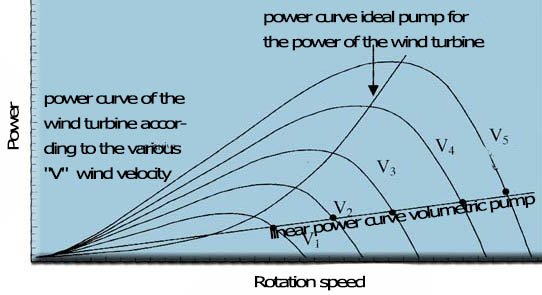

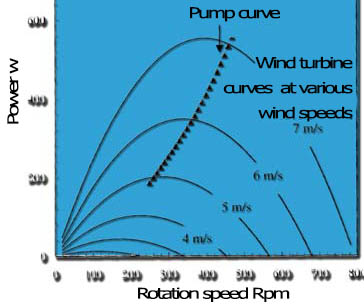

The wind turbines pumps are designed to provide water. The need for water is such that the objective of the wind turbine pump will be slightly different from the wind turbine power generation. The windmill for pumping should be able to run on the largest possible range of wind, as the site of geographic location will no longer be selected for profitability,but from duty to produce water throughout the dry period.

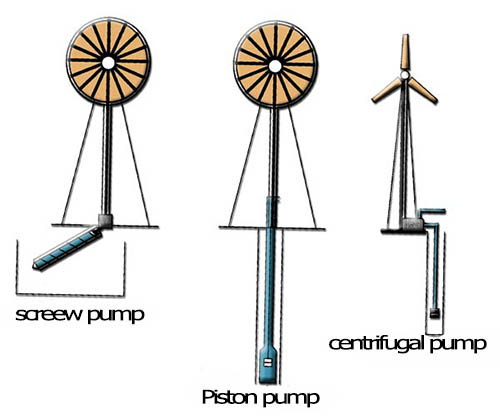

there are several categories of wind pumps depending on the type of pump that they operate:

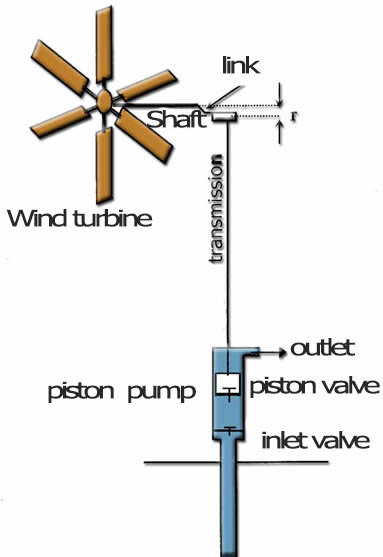

- wind turbine piston pump

- windmill pump screws

- wind turbine centrifugal pump

- wind turbine electric pump

- High specific speeds

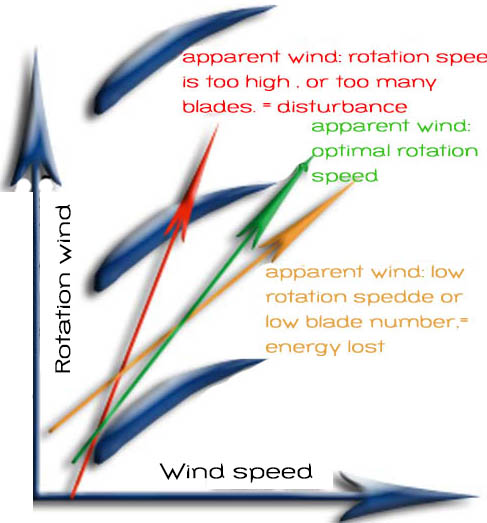

benefits disadvantages Captures the energy with a low blade number, thus providing the benefits of the low number of blades: economic cost in manufacturing the apparent wind and the angles of incidence of profiles section generate a bad alignment of lift and drag forces , with the plane of rotation, This requires good profiles quality sometimes difficult to achieve. Rotating tangential flow downstream of the propeller Revelle energy lost by the system. At equal power (Pw = torque nm x speed rad rotation / sec), a high rotational speed uses less torque generated so less losses. sometimes requires assistance of starting when the starting torque is insufficient speed of rotation closer to generator system (the price of the generator and gear box will be lower) speed of rotation and torque not suitable for pumping limited exposure to violent winds

- low specific speed

wind turbine piston pump an screw:

benefits disadvantages Allows the use of simple forms blades economic cost in manufacturing to get a good performance it takes a lot of blades (more expensive, heavier, to the wind when storms ...) start even at low wind speeds Rotating tangential flow downstream of the propeller Revelle energy lost by the system. At equal power (Pw = torque nm x speed rad rotation / sec), a low rotational speed uses more torque generated so more losses. speed of rotation and torque suited for pumping speed of rotation far to generator system (the price of the generator and gear box will be higher)

The slightest breath of air should be used, and the operating torque required to operate a piston pump is much higher than that of an electric generator. To generate torque on the propeller shaft of the wind turbine at the start, so at low speed, it will use all the energy of the wind passing through the propeller.

- the cost of the blades, to be many, increases the cost of the pumping system.

- The alternating movement pumping means that the fluid velocity increases from 0 to a maximum. The maximum speed is much higher than for a centrifugal pump. This generates pressure losses that can be eight times greater than for continuous pumping speed. The losses cause pressure that have an impact on the effort and wear of mechanical. This forces oversizing.

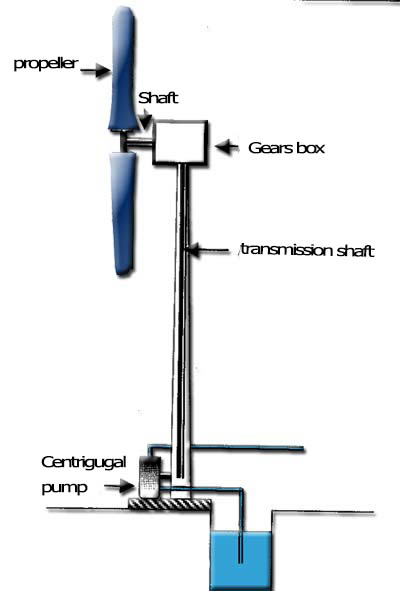

The pumping windmills operating a centrifugal pump have a lower torque operation, therefore the number of blades can be reduced

.

.

Systems of electric pumps coupled to the wind power generation is an attractive solution and has some advantages:

- Possibility of delocalize the production of electricity from the place pumping. We can install the wind turbine on a windy terrain and conduct electricity to pump disposed at the level to pump.

- The pump can be placed at the bottom of the well, and allow pumping more than 8 meters depth, which was sometimes unavailable with other turbines..

- The production of electricity can be used for other electrical appliances.

Global site map

Global site map Mecaflux

Mecaflux Tutorials Mecaflux Pro3D

Tutorials Mecaflux Pro3D Tutorials Heliciel

Tutorials Heliciel Mecaflux Store

Mecaflux Store Compare software functions

Compare software functions Quotes, Orders, Payment Methods

Quotes, Orders, Payment Methods project technical studies

project technical studies